Cantilever Racking – The Ideal Storage Solution for Long & Bulky Items

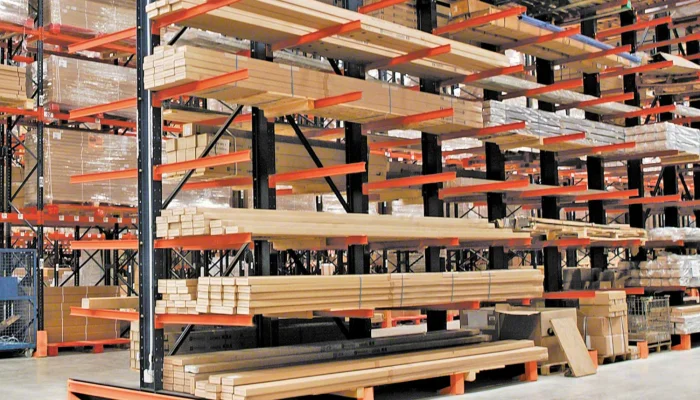

Designed for warehouses, manufacturing facilities, and retail storage areas, cantilever racking offers an open, obstruction-free storage system that enhances accessibility and maximises space utilisation.

Whether you need to store timber, pipes, metal sheets, or furniture, cantilever racking is a highly adaptable and durable storage system that optimises warehouse efficiency and safety.

Whether you need to store timber, pipes, metal sheets, or furniture, cantilever racking is a highly adaptable and durable storage system that optimises warehouse efficiency and safety.

What is Cantilever Racking?

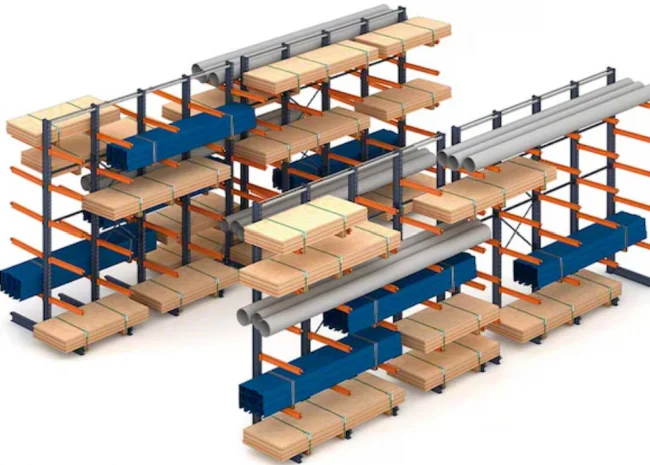

Cantilever racking is a robust storage system that features horizontal arms extending from upright columns. Unlike traditional pallet racking, it eliminates the need for front vertical posts, providing unrestricted access for forklifts and other handling equipment. This makes it particularly effective for storing long, heavy, or oversized items that are difficult to manage with standard shelving or racking systems.

Its versatile and modular design allows businesses to customise configurations to accommodate different product dimensions, ensuring an efficient and cost-effective storage solution.

Its versatile and modular design allows businesses to customise configurations to accommodate different product dimensions, ensuring an efficient and cost-effective storage solution.

Why Choose Cantilever Racking for Your Warehouse?

Cantilever racking is an essential storage system for businesses that need to manage oversized goods efficiently. Some of its key advantages include:

- Unobstructed Access

Unlike conventional pallet racking, cantilever racking has no vertical obstructions at the front of the arms. This makes it significantly easier to load and unload materials using forklifts, sideloaders, or manual handling.

- Exceptional Versatility

The adjustable arms can be modified to accommodate different load sizes, ensuring flexibility when storing a range of products, from lightweight PVC pipes to heavy-duty steel beams.

- Maximises Storage Capacity

Cantilever racking can be designed as a single-sided system, positioned against a wall, or as a double-sided system, allowing access from both sides and doubling storage space.

- Heavy-Duty Load Bearing

Built with high-strength materials, cantilever racking can support light, medium, and heavy loads, making it suitable for industries such as construction, timber supply, steel fabrication, and furniture warehousing.

- Improved Warehouse Organisation

By keeping bulky items off the floor and systematically arranged, cantilever racking improves stock visibility and enhances overall warehouse efficiency and safety.

Structure & Components of Cantilever Racking

Cantilever racking is engineered for strength, stability, and customisation. It consists of several key components that work together to support various storage needs.

- Bases

- The foundation of the racking system, anchored to the warehouse floor to provide stability.

- Designed to support the upright columns and absorb the load weight.

- Upright Columns

- Vertical structures that form the backbone of the system.

- Available in different heights and load capacities to suit specific storage requirements.

- Cantilever Arms

- Horizontal load-bearing arms that extend outward from the uprights.

- Adjustable to different heights to accommodate products of varying dimensions.

- Available in light-duty, medium-duty, and heavy-duty configurations.

- Bracing

- Cross-bracing and horizontal bracing are used to reinforce the structure and enhance stability.

- Helps prevent movement and ensures safe weight distribution.

- Optional Decking

- Timber, wire mesh, or steel decking can be added to create a solid shelf surface.

- Useful for storing smaller or non-uniform items that require additional support.

Types of Cantilever Racking

1. Single-Sided Cantilever Racking

- Features arms extending from one side of the upright columns.

- Typically placed against a wall or perimeter to maximise floor space.

- Ideal for warehouses with limited storage areas.

2. Double-Sided Cantilever Racking

- Features arms extending from both sides of the uprights.

- Provides twice the storage capacity and is ideal for central warehouse locations.

- Allows for easy access from multiple angles, improving warehouse efficiency.

- Features arms extending from one side of the upright columns.

- Typically placed against a wall or perimeter to maximise floor space.

- Ideal for warehouses with limited storage areas.

2. Double-Sided Cantilever Racking

- Features arms extending from both sides of the uprights.

- Provides twice the storage capacity and is ideal for central warehouse locations.

- Allows for easy access from multiple angles, improving warehouse efficiency.

Health & Safety Considerations

At Mowbray, we ensure that all cantilever racking systems comply with SEMA (Storage Equipment Manufacturers’ Association) and FEM (European Materials Handling Federation) safety standards.

Essential Safety Features:

Essential Safety Features:

- Load Signage: Clearly marked weight capacities to prevent overloading.

- Rack Guards & Barriers: Protect against forklift damage and accidental impacts.

- Secure Anchoring: All racking systems are securely fixed to the floor for maximum stability.

- Regular Inspections & Maintenance: Ensuring long-term durability and compliance with health & safety regulations.

Why Choose Mowbray for Cantilever Racking?

Mowbray provides expertly designed and custom-fitted cantilever racking systems that help businesses optimise storage and streamline operations. Our services include:

Free On-Site Warehouse Assessment – Helping you determine the best racking solution for your specific needs.

Tailored Racking Designs – Custom-built cantilever racking to fit your available space and load requirements.

Professional Installation – Expert installation by experienced technicians, ensuring safety and compliance.

Ongoing Maintenance & Support – Keeping your racking system in top condition for long-term efficiency.

Free On-Site Warehouse Assessment – Helping you determine the best racking solution for your specific needs.

Tailored Racking Designs – Custom-built cantilever racking to fit your available space and load requirements.

Professional Installation – Expert installation by experienced technicians, ensuring safety and compliance.

Ongoing Maintenance & Support – Keeping your racking system in top condition for long-term efficiency.

FAQs

- How much does cantilever racking cost?

The cost of cantilever racking depends on factors such as racking size, load capacity, material type, and installation complexity. Contact Mowbray for a bespoke quote tailored to your warehouse requirements.

- Can cantilever racking be customised?

Yes! Our cantilever racking systems can be custom-designed, with adjustable arms, different load capacities, and optional decking to suit your storage needs.

- Is cantilever racking suitable for outdoor use?

Absolutely! Galvanised cantilever racking is available for outdoor storage, offering weather-resistant durability for materials exposed to the elements.

- Do you offer installation and maintenance services?

Yes! We provide full installation, routine inspections, and ongoing maintenance to ensure your racking system remains safe and efficient.

Get in Touch

Looking for high-quality cantilever racking for your warehouse?

Contact Mowbray today for expert advice, a free consultation, and tailored storage solutions.

Services we are offering

Mowbray will guide your project from the initial planning and design stage through to completion, providing exceptional service and expertise every step of the way.

We can also apply for building regulations on your behalf and provide risk assessments and method statements.